what are the functions of cone crusher

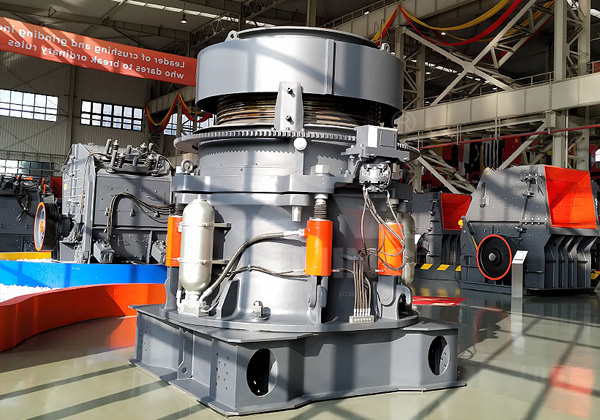

A cone crusher is a type of compression crusher used in the mining and construction industries to crush materials. It functions by using a rotating cone inside a chamber to apply force to the material, breaking it into smaller pieces. The primary function of a cone crusher is to reduce the size of large rocks or ore so that they can be processed further or used in construction. The crusher consists of a cone-shaped mantle and a concave surface, with the material being squeezed between these two components, which causes it to break down.

One of the core functions of a cone crusher is its ability to handle a variety of materials. Whether it’s hard rocks, ores, or aggregates, the cone crusher is versatile in processing different types of material. It works efficiently with materials such as granite, basalt, limestone, and more. Its ability to handle a wide range of materials makes it a popular choice for many industries, including mining, quarrying, and construction.

Another function of a cone crusher is its efficient size reduction capabilities. Unlike other crushers, the cone crusher has a unique design that allows for a consistent and uniform reduction ratio. This means that the output size can be controlled more precisely, making it ideal for producing a specific particle size or uniformity in the final product. This feature is particularly useful in industries where consistency in material size is critical, such as in concrete or asphalt production.

In addition to its size reduction capabilities, cone crushers also provide high production capacity. This makes them highly efficient in large-scale operations where large quantities of material need to be processed. The crusher’s design allows it to work continuously for long hours without significant wear and tear. This efficiency makes it a preferred choice in large mining operations and aggregate production plants.

Lastly, cone crushers offer safety and ease of operation. With modern technological advancements, many cone crushers are now equipped with automated systems for adjusting settings, monitoring performance, and maintaining safety standards. The automation feature helps in minimizing downtime, reducing operational costs, and ensuring the safety of workers. Additionally, the crusher’s design allows for easy maintenance, which contributes to its longevity and reliability in heavy-duty applications.