rock crushing production line solutions

A rock crushing production line is a highly efficient and essential solution for the mining, construction, and aggregate industries. This process involves multiple stages that work together to break down rocks into smaller, usable sizes for a variety of applications such as construction materials, road base, and gravel. The combination of crushers, screens, and other equipment enables the creation of high-quality aggregates for various projects. If you’re looking to set up or optimize a rock crushing production line, understanding its components and how they function together can help ensure you get the best results.

Key Components of a Rock Crushing Production Line

1. Primary Crusher: The primary crusher is the first line of defense in any rock crushing production line. Jaw crushers, gyratory crushers, or impact crushers are commonly used at this stage to break large rocks into smaller, manageable pieces. Jaw crushers are widely used due to their ability to crush a variety of materials and their durability in handling hard materials like granite, basalt, or limestone. The size of the material is reduced in this first stage, setting the foundation for further processing.

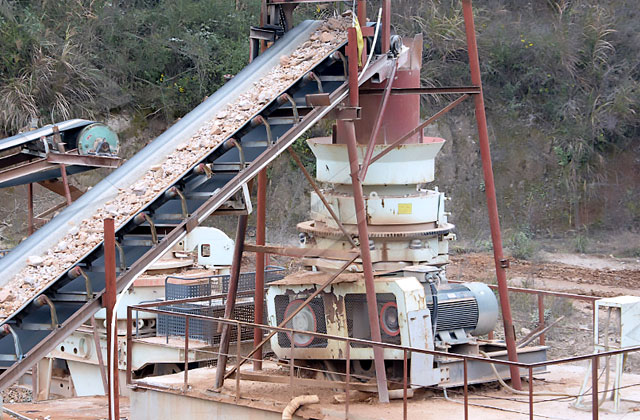

2. Secondary Crusher: Once the material is reduced in size by the primary crusher, it is passed to the secondary crusher, which further reduces the material size for specific applications. Cone crushers, impact crushers, or hammer mills are often employed at this stage to achieve a finer product. Secondary crushers are particularly important for creating the ideal particle shape for specific industries like asphalt production or concrete manufacturing.

3. Screening: After the secondary crushing, the material is fed into vibrating screens or other types of screening equipment to separate fine materials from coarse aggregates. Screening is essential to ensure that the final product meets specific size specifications for different applications. A range of screen sizes allows for the separation of fine materials such as sand or gravel from larger stones, ensuring that the aggregates meet construction standards.

4. Sand Production: For some production lines, especially in construction and concrete manufacturing, the creation of sand is an essential component. A vertical shaft impact crusher (VSI) or sand making machine is often incorporated into the process. These crushers break down stones into finer particles and produce high-quality sand that meets the required specifications for strength and durability in construction applications.

5. Conveyors and Feeders: Material handling is a critical part of any rock crushing production line. Conveyors and feeders are used to transport material from one stage of the process to the next, ensuring the smooth flow of production. These systems are designed to move large quantities of material efficiently, reducing downtime and improving the overall productivity of the plant.

6. Control System: The control system of a rock crushing production line manages the flow of material between crushers, screens, and other equipment. Modern control systems are integrated with automated technology that adjusts settings to optimize the crushing process, ensuring consistent production quality and maximum output. With sophisticated monitoring tools, operators can make real-time adjustments, improving efficiency and reducing operational costs.

Advantages of a Rock Crushing Production Line

A well-designed rock crushing production line offers several benefits, including:

-

High Efficiency: Automated systems and optimized equipment work together to ensure the production line runs efficiently, maximizing output while minimizing energy consumption and downtime.

-

Customization: The process can be tailored to meet the specific needs of different projects, whether that’s creating fine sand for concrete or large aggregates for road construction.

-

Cost-Effective: By utilizing a full production line, operators can significantly reduce the need for manual labor and increase the yield of valuable materials.

-

Environmental Sustainability: Advanced dust suppression and noise reduction technologies can be incorporated into the production line to reduce its environmental impact, making it a more sustainable choice for large-scale operations.

A rock crushing production line is an essential asset for industries requiring high-quality aggregates. By using a combination of crushers, screens, and conveyors, a rock crushing plant can efficiently break down large rocks into small, usable materials. When designed and operated effectively, a rock crushing production line offers numerous benefits, including higher productivity, cost savings, and environmental sustainability. Whether you’re working in construction, mining, or any other sector that needs crushed aggregates, investing in a reliable rock crushing production line will ensure long-term success.