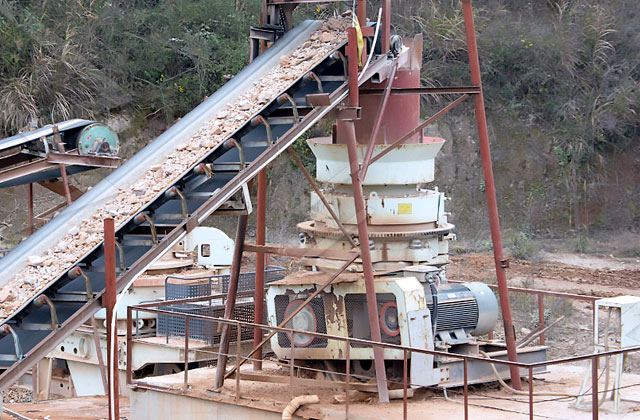

Quarrying equipment with main crusher

Quarrying is a crucial industry that provides raw materials for construction, infrastructure, and various industrial applications. At the heart of every quarrying operation lies efficient machinery, with the main crusher playing a pivotal role. This article explores the key quarrying equipment, focusing on different types of crushers and their functions in stone processing.

Core Quarrying Equipment Overview

A well-equipped quarry requires various machines for drilling, blasting, crushing, screening, and transporting materials. The essential quarrying equipment includes:

- Drilling & Blasting Equipment

- Drill rigs, hydraulic hammers, and explosives for rock fragmentation.

- Loading & Hauling Equipment

- Loaders, excavators, and dump trucks to move raw materials.

- Crushing Equipment – The Heart of Quarrying

- Primary, secondary, and tertiary crushers refine raw rock into usable aggregates.

- Screening & Washing Equipment

- Vibrating screens, classifiers, and sand washers ensure proper grading.

- Conveying Systems

- Belt conveyors transport crushed material between processing stages.

The Role of Crushers in Quarrying Operations

The main crusher determines productivity, energy efficiency, and final product quality. Key types include:

1. Jaw Crusher (Primary Crushing)

- Best For: Hard and abrasive rocks (granite, basalt).

- Advantages: High reduction ratio, simplicity, and reliability.

- Applications: Primary crushing stage for large stone blocks.

2. Cone Crusher (Secondary Crushing)

- Best For: Medium-hard to hard rocks.

- Advantages: Efficient particle shaping, high throughput.

- Applications: Producing finely crushed aggregates or railway ballast.

3. Impact Crusher (Versatile Crushing)

- Best For: Medium-hard materials (limestone, recycled concrete).

- Advantages: Excellent cubical-shaped output.

- Applications: Producing high-quality construction sand and gravel.

4. Gyratory Crusher (High-Capacity Crushing)

- Best For: Large-scale operations with massive feed sizes.

- Advantages: Higher capacity than jaw crushers.

- Applications: Mining and mega-quarries requiring constant output.

Choosing the Right Crusher

Selecting the correct crusher depends on several factors:

- Rock hardness & abrasiveness

- Desired output size

- Production capacity

Quarrying equipment must be carefully selected based on material properties and production goals. The main crusher dictates efficiency and product quality, making it the backbone of any quarry. Whether it’s a jaw crusher, cone crusher, or impact crusher, choosing the right machine ensures high productivity and sustainable operations.