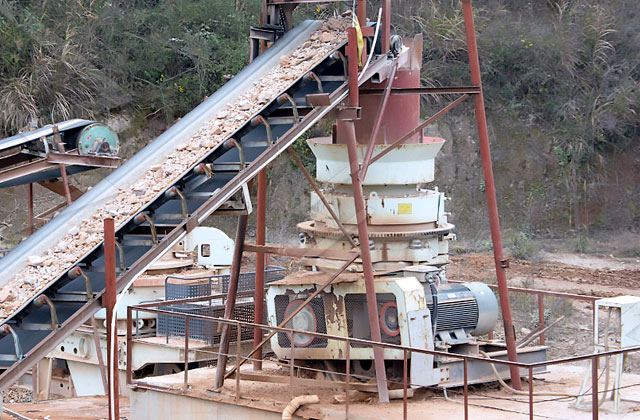

Stone crusher for concrete aggregate production

Concrete remains the most widely used construction material globally, and high-quality aggregates are essential to achieving strong, durable concrete. As infrastructure projects expand across the world—ranging from highways and bridges to urban buildings and industrial complexes—the demand for reliable aggregate production equipment continues to grow. Among these, stone crushers play a central role in producing the crushed rock needed for concrete applications.

What Is a Stone Crusher in Aggregate Production?

A stone crusher is a machine designed to reduce large rocks, ores, and construction stones into smaller pieces or sand-sized particles. These crushed materials are then used as aggregates in concrete mix designs. The performance and consistency of concrete depend significantly on the quality and gradation of these aggregates.

Types of Stone Crushers Used in Aggregate Production

Different stone crushers are used depending on raw material hardness, capacity requirements, and desired final product size. Common crusher types include:

1. Jaw Crusher

-

Primary crushing

-

Breaks large rocks into manageable sizes

-

Suitable for hard and abrasive materials like granite, basalt, and river stone

2. Cone Crusher

-

Secondary and tertiary crushing

-

Produces well-shaped aggregates with uniform grain size

-

Ideal for medium-hard to very hard materials (e.g., granite, basalt, ironstone)

3. Impact Crusher

-

Used for softer to medium-hard materials like limestone

-

Produces cubic-shaped aggregates ideal for concrete

-

High reduction ratio and good particle shape

4. Vertical Shaft Impact (VSI) Crusher

-

Sand making and shaping

-

Essential for producing fine aggregates and manufactured sand (M-sand)

-

Improves workability and strength of concrete

Crushing Process for Concrete Aggregates

The typical production flow includes:

-

Primary Crushing — Jaw crusher breaks the large stones.

-

Secondary Crushing — Cone or impact crusher further reduces size.

-

Tertiary Crushing / Shaping — VSI crusher produces fine aggregates or sand.

-

Screening & Grading — Vibrating screens classify aggregates by size.

-

Washing — Removes dust and impurities to improve concrete strength.

This systematic process ensures consistent aggregate size distribution and quality, critical for structural concrete performance.

Benefits of Using Stone Crushers for Concrete Aggregate

| Benefit | Description |

|---|---|

| Consistent size and shape | Ensures uniform mix and strong concrete bonding |

| Higher productivity | Efficient crushing systems offer large output capacity |

| Cost savings | Reduces dependency on natural sand and gravel sources |

| Versatility | Suitable for different stones and project needs |

| Sustainability | Manufactured sand option helps conserve river sand resources |

Key Features to Look for in a Stone Crusher for Aggregate Production

-

High crushing efficiency & low energy consumption

-

Strong crushing chamber design

-

Wear-resistant components

-

Easy maintenance and long service life

-

Reliable automation and control systems

-

Flexible adjustment of final product size

Conclusion

In modern construction, stone crushers are indispensable machines for producing high-quality aggregates essential for concrete production. With advancements in crusher technology—from jaw crushers to VSI sand makers—contractors and mining companies can produce consistent, durable, and economical aggregates to meet growing infrastructure demands.

Choosing the right crusher equipment not only boosts efficiency but also ensures long-term performance and sustainability in aggregate production.