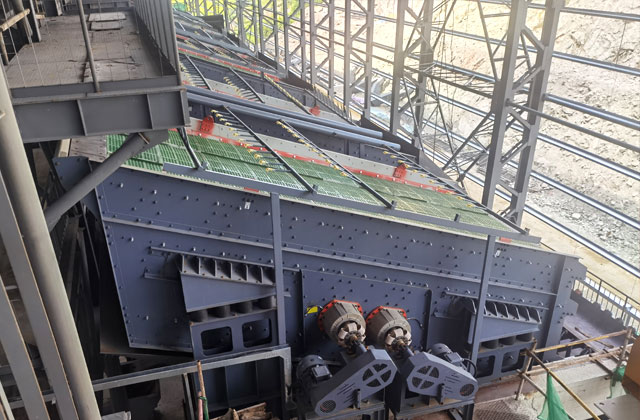

Sand and gravel screening machine for quarry

In the quarrying industry, sand and gravel are essential raw materials used in construction, road building, concrete production, and many other applications. Efficiently separating and classifying these materials by size is critical to ensuring quality and meeting industry standards. This is where sand and gravel screening machines come into play, offering a practical solution to optimize aggregate processing at quarries.

What is a Sand and Gravel Screening Machine?

A sand and gravel screening machine is a mechanical device designed to separate bulk materials into various size fractions by passing them through a series of screens or meshes. This equipment helps remove unwanted debris, oversized rocks, and fine particles from sand and gravel, producing uniform and usable aggregates tailored to specific construction needs.

Importance of Screening in Quarry Operations

-

Quality Control: Screening ensures that the gravel and sand meet the size and cleanliness standards required by clients or construction regulations.

-

Efficiency: By sorting materials efficiently, the screening machine reduces the need for secondary crushing or washing, saving time and operational costs.

-

Maximized Output: Proper screening maximizes the usable output from raw materials, reducing waste.

-

Improved Product Consistency: Uniform aggregate size leads to better compaction and strength in concrete or asphalt mixes.

Types of Screening Machines Used for Sand and Gravel

The most common type used in quarries. It uses vibration to move materials across screens, separating particles by size. Vibrating screens can be single, double, or multi-layered for more precise sorting.

Features to Look for in a Screening Machine

-

Screen Size and Deck Configuration: Depending on the scale of operation and desired product gradation.

-

Durability and Material: Heavy-duty construction to withstand abrasive sand and gravel.

-

Ease of Maintenance: Quick screen replacement and simple cleaning reduce downtime.

-

Capacity and Throughput: Ability to handle the quarry’s daily output volume efficiently.

-

Mobility: Portable screening units provide flexibility for mobile quarry setups.

Applications of Sand and Gravel Screening Machines

-

Quarry Aggregate Processing: Screening raw materials extracted from quarries to produce construction-grade sand and gravel.

-

Construction Projects: Supplying screened materials with specific sizes for concrete mixing, asphalt production, and landscaping.

-

Recycling: Screening construction debris and separating reusable sand and gravel from waste.

In quarry operations, the sand and gravel screening machine is indispensable for producing high-quality aggregate materials. By enhancing material quality, improving operational efficiency, and increasing productivity, screening machines help meet the growing demand for high-quality sand and gravel in the construction industry. Choosing the right screening equipment tailored to specific quarry needs can significantly impact profitability and sustainability.