Specifications and types of vibrating screens

Vibrating screens are an essential component in various industries, especially in the mining, aggregate, and construction sectors. They are used to separate materials based on size and to filter out unwanted particles. The specifications and types of vibrating screens vary depending on the intended application, the material being screened, and the desired output. Common specifications include factors like screen size, material, capacity, and vibration frequency.

One of the key specifications to consider when selecting a vibrating screen is the size of the mesh. The mesh size dictates the size of the particles that can pass through. Screens can have various mesh openings, ranging from very fine for sieving sand to larger openings for coarse materials like gravel. Another important specification is the capacity of the screen, which indicates how much material can be processed per hour. This is often measured in tons per hour (TPH) and can range from small screens handling tens of tons to larger ones managing hundreds of tons.

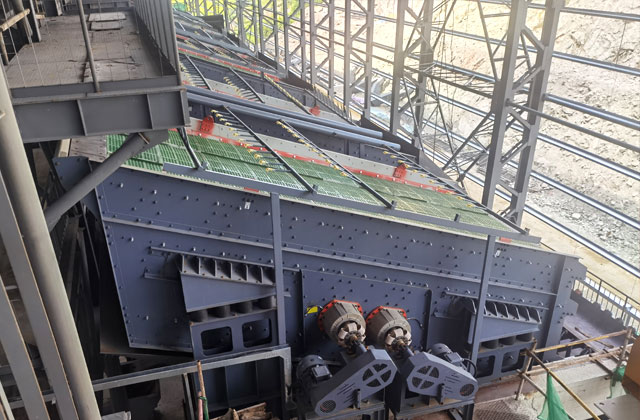

The type of vibrating screen can vary significantly depending on the application. The most common types include circular vibrating screens, linear vibrating screens, and elliptical vibrating screens. Circular vibrating screens are the most widely used, as they provide efficient separation for a wide range of materials. Linear vibrating screens are typically used for screening materials with less variability in particle size, providing a more straightforward movement that ensures uniform screening. Elliptical vibrating screens combine both circular and linear motion and are used for materials that require a more complex screening process.

Vibrating screens are made from a variety of materials to ensure they can handle the specific requirements of each application. For example, high carbon steel, stainless steel, and polyurethane are commonly used for their durability and resistance to corrosion. The choice of material is crucial for ensuring the screen can withstand the impact of abrasive materials, high temperatures, and the wear and tear associated with continuous operation.

Finally, the frequency of vibration plays an important role in the performance of vibrating screens. The vibration frequency can affect the material flow and separation efficiency. Higher frequencies generally provide better material stratification and finer separation, while lower frequencies might be used for heavier, coarser materials that require more force to be moved. Additionally, vibrating screens may be equipped with features such as variable speed drives or adjustable angles to enhance performance and adaptability for specific screening tasks.